LED Light Strips: Your Comprehensive Lighting Guide

LED strips have ushered in an exciting new age of versatile, efficient, and vibrant lighting options for both home and commercial spaces. But what exactly are these innovative strips? And what key considerations should you keep in mind to fully leverage their capabilities? This comprehensive guide explores the anatomy, functions, and expert recommendations to help you make the most of LED lights strips.

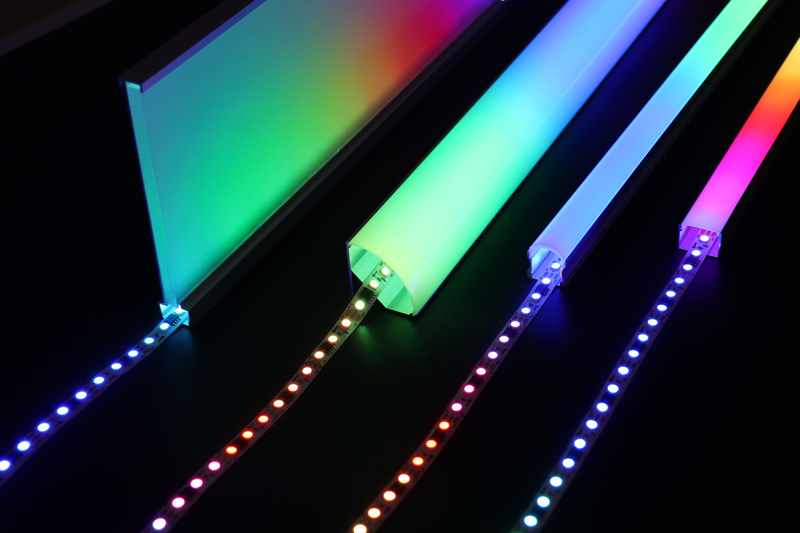

(LED strips)

What Are LED Strips?

As a primer, LED strips are slim, flexible circuit boards with surface-mounted light-emitting diodes that uniformly distribute vibrant light across their entire length. According to industry testing standards from Energy Star, a typical 5-meter strip can output up to 1200 lumens while only drawing about 24 watts - a testament to major advances in solid-state lighting technology. Their efficient, high-density illumination packs brightness ranging from 300 to upwards of 1000+ lumens per meter depending on intended use, making them suitable for everything from subtle accent lighting to illuminating expansive commercial spaces.

Anatomy of an LED Strip

Structurally, quality LED strips share certain key components:

LEDs: Tiny yet durable LED modules serve as the light source

Circuit Board: Flexible copper circuit boards to promote adjustability

Adhesive Backing: Adhesive backing for straightforward mounting

Protective Coating: Optional protective coatings for weatherproofing

(LED strip - Adhesive Backing)

LED strip performance indicators

Beyond physical construction, performance metrics are equally as important for determining appropriate LED strip models aligned to your unique needs:

Brightness & Power

As mentioned previously, output brightness is quantified in lumens/meter (lm/m), comparing overall light output per unit length. Depending on context such as accent versus task lighting, brightness recommendations vary widely from around 300 lm/m to over 1000 lm/m for workshops or retail displays where strong illumination is needed. Closely related, the LED density (number of LEDs packed per meter length) also factors into both potential brightness and necessary power draw - higher densities like 60 LEDs/meter enable greater luminosity on demand but consequently require higher voltage input typically around 14.4 watts per meter.

Color Quality & Customization

With inherent RGB capabilities, today's LED strips empower users with an extensive palette of colors and tones using variable voltage signals a major upgrade over legacy fluorescent or incandescent lighting limited to a single fixed color temperature. Based on the intended ambiance, strips now include both single color options for uniform appearance as well as multi-channel variants like RGB that offer dynamic lighting scenarios. For more tailored implementations, strips also provide adjustable white color temperatures, spanning a spectrum from warm, inviting yellow tones (2700K) up to cool crisp blue hues (6500K).

| Else | Recommendation & particulars |

| Input Voltage and Power Supplies | Most LED lights strips run on low voltage (12V or 24V) and require a compatible power supply. For example, a 5-meter-long strip drawing 14.4 watts per meter will need at least a 72-watt power supply. |

| Color Rendering Index (CRI) | CRI measures a light's ability to accurately render colors. LED lights strips with a CRI above 80 can portray objects more true to life, ideal for applications like art galleries or retail displays where color fidelity is vital. |

| PCB Quality | The thickness of the printed circuit board (PCB) directly impacts heat management and durability. Choose a PCB with at least 2 oz copper for superior thermal stability and longer lifespan. Branding & Warranty: Opting for a recognizable LED lights strips brand often means higher quality assurance and reliable customer support. Check warranty terms to ensure your investment is well-protected. |

| Performance Testing | Before purchasing, test LED lights strips' brightness and color temperature when possible to ensure they meet your needs, especially performance over time in terms of consistent brightness and hue. |

Correct power supply and installation of LED strip

Beyond standalone performance metrics, properly powering and installing strips also remain critical for lighting success:

Properly powering and installing the strips are critical steps that can make or break your lighting project. Although LED strips simply plug in, verifying compatible voltage and amperage prevents issues down the road. For low voltage strips, switching power supplies safely transforms electricity to the needed levels.

-

Soldering & Connector Options

Direct Soldering: For permanent installations, directly soldering points together create the most rugged bonds. Ensure joints are clean and secure to maintain steady current flow.

Clip Connectors: For non-permanent placements requiring flexibility, clip connectors are the ideal choice, easy to install and adjust. Select connectors compatible with your LED strip model.

(LED strip - Soldering)

-

Maintaining Voltage Consistency

Regardless of connection methods, verify all contact points are tightly secured to prevent voltage drops and strip flickering.

-

Aluminum Channels & Heatsinks

The connection method used when installing strips also affects durability. Soldering strips together creates permanent, rugged bonds while clip connectors allow for adjustability in temporary setups. Regardless of the approach, securely fastening contact points prevent flickering from voltage drops.

-

Aesthetics & Protection

LED Channels provide a streamlined, finished look while shielding strips from harm.

Heat Dissipation: Effectively drawing heat away from high-power LEDs to promote longevity.

(Ceiling application of LED strip & LED channel)

-

Choosing Appropriate LED Channels

Select LED channels suited to your mounting location and strip types. For example, embedded channels work well on smooth surfaces while corner channels fit nicely where walls meet ceilings. For outdoor applications, IP65 and IP67-rated channels shield strips from environmental factors. Properly installing channels protects strips while enhancing the lighting ambiance.

Conclusion

While LED lights strips technology has certainly simplified previously complex lighting challenges, like any electrical implementation minding key details makes all the difference in achieving your intended ambience goals. Let us know if you have any other questions on leveraging strips for your unique space!

FAQ

Q1: Can I link multiple LED strip rolls for longer runs?

A1: Connector cables allow daisy chaining multiple rolls of LED strips to achieve longer overall lengths like for cove or perimeter lighting.

Q2: How do I cut LED strips to length?

A2: Use sharp scissors or wire cutters to snip strips along designated cut points, usually located every 2-4 inches and marked by copper pads. Never cut along the middle of strips between pads.

Q3: How do LED temperature settings work?

A3: LED controllers allow adjusting color temperature, measured in degrees Kelvin (K). Lower Kelvin ratings around 2700K emit a warm, cozy glow while higher temperatures near 6500K produce crisp, invigorating blue-tinted light.

Q4: Do LED strips require special dimmers?

A4: LED dimming requires either PWM (pulse width modulation) or 0-10V dimmers designed specifically to avoid flickering and incompatibility issues common with traditional dimmers.

Q5: Is hyper-bright 30,000 lumens lighting safe for the eyes?

A5: Extremely high lumen densities could cause glare or eye strain without proper diffusion. Opt for strips with silicone lenses or diffuser covers for comfortable vivid lighting.

References:

Further Reading:

ABOUT THE AUTHOR

.jpeg?w=800&h=600)